Tube Sheet Double Stainless Steel: 1.4462, F51, S31803; F60, S32205; F53, S32750;Stainless Steel: F304L,F316L, F312L

Introduction

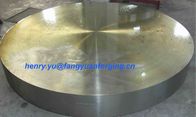

Large-diameter disc also called flange, which is one of the flanges, widely used and popularized in the machinery industry, chemical industry, wind power industry and sewage treatment industry, which has been praised and favored by users. The production process is divided into rolling and forging, the material usually use carbon steel, stainless steel or alloy steel.Our company can produce different type large flange accroding to the customer's drawing and requirments,if you have any questions,please contact with us freely

Material:

Double Stainless Steel: 1.4462, F51, S31803; F60, S32205; F53, S32750

Stainless Steel: F304L,F316L, F312L

Hastelloy: Inconel 625 & Monel K500

Carbon Steel, ASTM A105, ASTM A350 LF2 : ASTM A694 F60/65 S355J2G3

Standard: EN,DIN,ASME,ASTM,ASME,API, BS,JIS, ANSI,UNI,GOST

Melting process: EF+LF+VD; VOD, AOD, ESR

Process: Raw material inspection →Cutting→ inspection → Preheat → forging → heat treatment → inspection → rough machining → NDT → According to material Tech. heat treatment →Testing → finishing machining →NDT →inspection → packing→ Delivery.

Heat Treatment:

Carbon Steel treatment:N or N+T

Alloy Steel treatment: N, A or Q+T

Stainless Steel treatment: S

Parameters

|

Material

|

Carbon steel,Alloy steel,42CrMo,35CrMo,Q345

|

|

Weight

|

Max 1000kg per piece

|

|

Structure

|

Forging, plate

|

|

Type of flange

|

large diameter flange, welding flange

|

|

Heat treatment

|

Quenching and tempering

|

|

Process

|

forging, rough machining, QT, finish machining

|

|

Main equipments

|

6m.4m CNC planer type milling machine, VMC850, 5m CNC vertical lathe,6m CNC horizontal boring machine etc.

|

|

Precision of gear

|

can up to 0.05mm

|

|

Inspection

|

Raw material inspection, UT,physical property test,dimension inspect

|

|

Application

|

boiler and pressure vessel, petrochemical industry, power plant, ship manufacture and mining machinery

|

Testing Lab:IOS/IEC 17025:2005/ CNAS

Dimension: OD up to5000mm; Thickness up to 500mm; Height up to 1500mm

And as per customer design requirements

Weight: Max. 80 tons

About Us

Jiangyin Fangyuan Ringlike Forging & Flange Co.,Ltd, established in 1993, is the member of the Confederation of Chinese Metalforming Industry, Chinese wind energy association, China petroleum & Petro-chemical Equipment Industry Association. As one of the biggest ring forging manufacturers in China, our company is specialized in manufacturing wind power gear rings, wind-tower flanges, wind power main shafts, ring forgings and pressure vessel forgings.

Our company covers a total area of 100,000 m2, including building area of 70,000 m2.

The main equipments: 5 hydraulic press machine (800T,1600T,2000T,3500T,3600T), 4 ring rolling machine (2000,2500,3500,5000mm), 5 charging machine (5—20T), 7 operation machine, 48 vertical lathes, 2 CNC drilling machine (5m), 50 horizontal lathes, etc.

The annual capacity of our company is 150,000 tons.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!