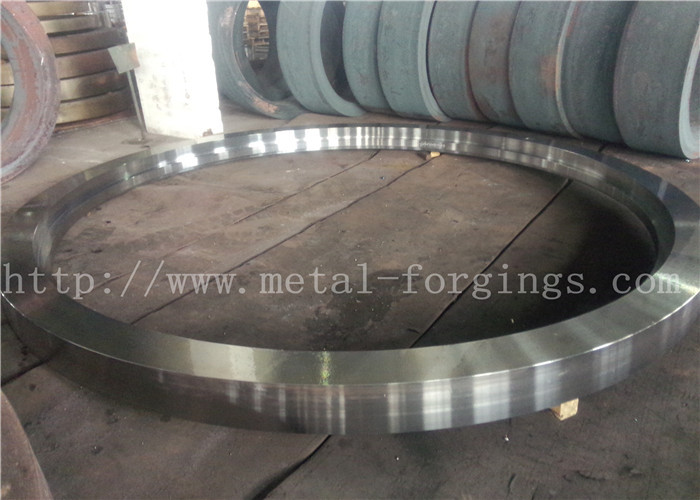

Max OD 5000mm A350 LF3 LF6 Carbon Steel Forged Rings Rough Machined Q+T Heat Treatment

Steel Forged Rings Introduction

Seamless forged rings can be produced by a process called ring rolling. Ring roll production begins with a circular preform of metal that has been pierced (using the open die forging process) to form a “ring blocker”. This blocker is then reheated to the proper temperature for that grade of material and placed over a mandrel. The mandrel then moves to a drive roll (king roll) that rotates under pressure to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the ring forging.

Depending on the size, seamless rings can also be produced by simple piercing of a forging, either open die or with the outside diameter contained in a tool. Other manufacturing methods such as mandrel rolling under a hammer or press or drawing the material over a mandrel bar. We uses all of these methods to produce seamless forged rings of the highest quality and integrity.

ASTM/ASME Standard A350 LF2(%)

| C≤0.20 |

Si:0.25~0.35 |

Mn:≤0.90 |

S≤0.035 |

P≤0.040 |

| Cu≤0.40 |

Ni:3.3~3.7% |

Mo≤0.12 |

V≤0.03 |

Cr≤0.30 |

Heat Treatment::Quenching+ Tempering

| Item |

LF2 Class1 and LF2 Class2 |

| Tensile Strengthd |

485~655 Mpa |

| Yield Strengthd |

≥ 260 Mpa |

| Elongation Rate |

≥ 22% |

| Reduction Of Area |

≥ 35% |

Hardness ≤ 187HB

| Item |

Temperature |

Min average impact enery |

Min impact energy |

| LF2 Class1 |

-101℃ |

20J |

16J |

| LF2 Class2 |

-101℃ |

27J |

20J |

Largest OD:5000mm

Largest Weight:15000kg

Surface Finish 6.3um Ra Or As Required.

Forging Reduction Min:3.1 Or As Required

The main manufacturing equipments:

|

Name&Description

|

Capacity

|

Quantity

|

|

3600Thydraulic press

|

Max. single forging in 18T

|

1

|

|

2000T hydraulic press

|

Max. single forging in 9T

|

2

|

|

800 hydraulic press

|

Max. single forging in 5T

|

1

|

|

6T electrical hydraulic hammer

|

Max.single forging in 5T

|

1

|

|

3T electrical hydraulic hammer

|

Max.single forging in3T

|

1

|

|

Air hammer

|

Max.single forging from250kg to 1000kg

|

7

|

|

Forging operation machine

|

Max.singe forging from20T-5T

|

7

|

|

Heat treatment Furance

|

Max.8000*5000*1500mm

|

11

|

|

CNC driling machine

|

Max.5000mm

|

2

|

|

Vertical lathe

|

From 1600 to 5000mm

|

60

|

|

Horizontal lathe

|

Max.5000mm

|

70

|

|

Band sawing machine

|

260-1300mm

|

36

|

Test instruments:

Certfiticates List:

| Certificates list of Jiangyin Fangyuan |

| ISO9001:2008 |

ISO14001:2004 |

PED Certificate |

| ABS Certficate |

BV Certficate |

DNV Certificate |

| RINA Certficate |

GL Certficate |

LR Certficate |

| CCS Certficate |

NK Certficate |

KR Certficate |

| API-6A Certficate |

API-17D Certficate |

CNAS Certficate |

Company Introduction:

Jiangyin Fangyuan Ringlike Forging Flange Co.Ltd was established in 1993.It’s the member of the Confederation of Chinese Metalforming Industry, Chinese wind energy association, China petroleum & Petro-chemical Equipment Industry Association.

As the leading forging manufacturer in China, our company is specialized in manufacturing forged rings, forged discs, forged shaft ,flanges,valve forging and pressure vessel forgings.

The company covers a total area of 100,000 m2 (square meters), building area of 70,000 m2(square meters). There are 600 staffes in the company. Among them, there are 138 senior engineers and technicians. We also have our own testing center lab. which is able to do chemical analysis, metalloscope test, spectrometer test, mechanical property test and Ut test.

The company has been proved by ISO9001,ISO14001, TUV, API,LRS, GL,BV, ABS,DNV, CCS ,RINA,KR and NK.

The GE,SKF ,ABB and Siemens are our main forgein customers now.I hope that my company could have the opportunity to established a long-term cooperative relationship with you.I hope to receive your inqury soon.

Products process:

The forgings manufacturing and inspecting process are showed in the following picture :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!