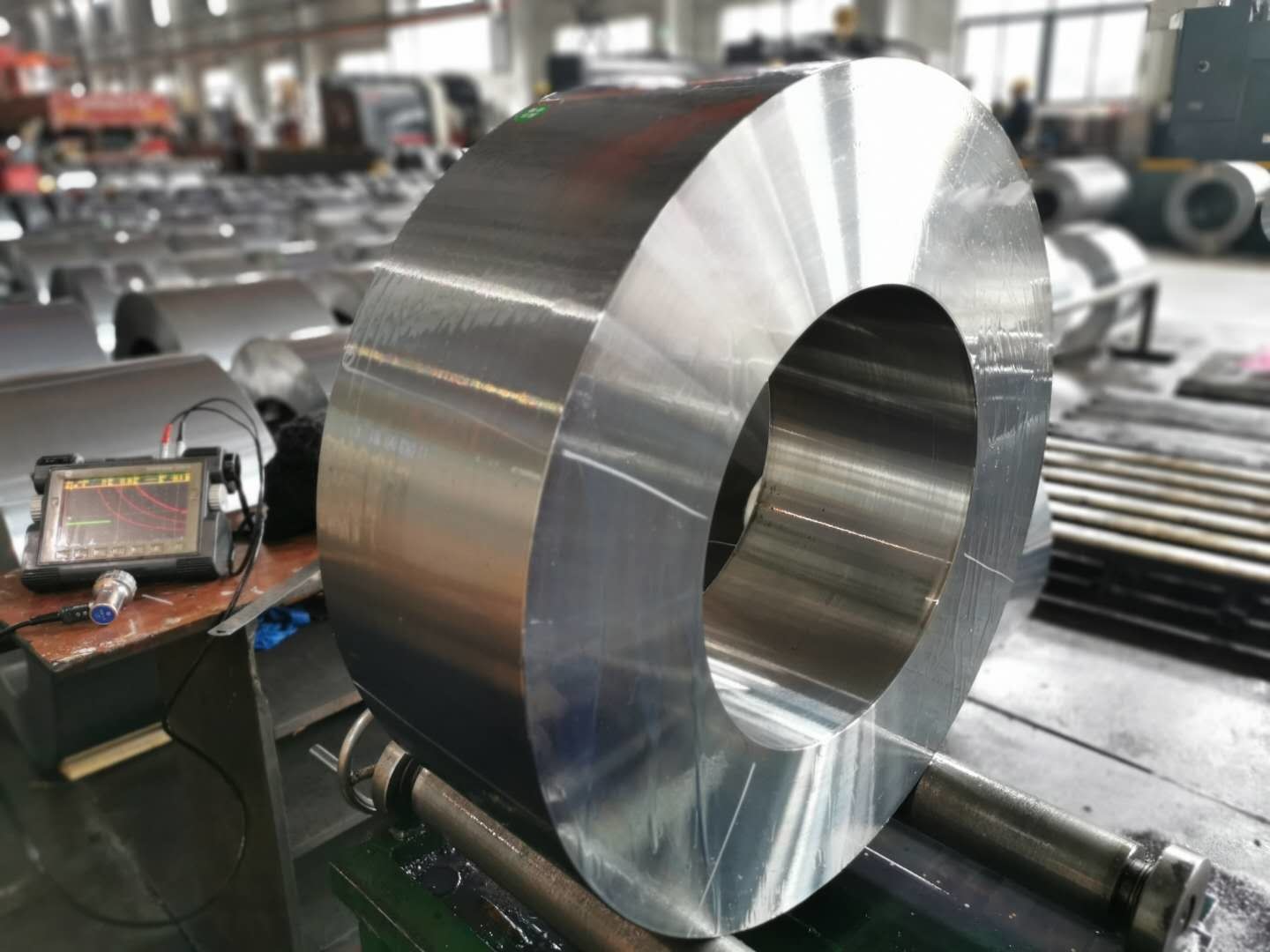

Corrosion Resistance Mild Steel Rings , Stainless Steel Forged Rings

Mild Steel Rings Introduction

Forging seamless rolled rings on one of our radial ring rollers is southwest aluminum specialty. The process for ring forging for the seamless rolled forged ring involves cutting a hole out of a forging material.The rolled forged rings offer improved concentrically and smooth surfaces as compared to plate burn-outs, or butt welded rings.

Mild Steel Rings Details

<1> Chemical composition: of ASTM/ASME Standard A105

| C≤0.35% |

Si≤0.35% |

Mn:0.6~1.05% |

S≤0.05% |

P≤0.04% |

| Cu≤0.4% |

Ni≤0.4% |

Mo≤0.35% |

V≤0.08% |

Cr≤0.3% |

<2> Heat Treatment:

|

Normalizing,

Normalizing+Tempering

Quenching+ Tempering

|

<3> Mechanical Properties:

| Tensile Strengthd |

≥ 485 Mpa |

| Yield Strengthd |

≥ 250 Mpa |

| Elongation Rate |

≥ 22% |

| Reduction Of Area |

≥ 22% |

| Hardness |

≤ 187HB |

<4> short Introduction:

|

Largest OD:5000mm

Largest Weight:15000kg

Surface Finish 3.2um Ra Or As Required.

Forging Reduction Min:3.1 Or As Required

|

<5> The main manufacturing equipments:

|

Name&Description

|

Capacity

|

Quantity

|

|

3600Thydraulic press

|

Max. single forging in 18T

|

1

|

|

2000T hydraulic press

|

Max. single forging in 9T

|

2

|

|

800 hydraulic press

|

Max. single forging in 5T

|

1

|

|

6T electrical hydraulic hammer

|

Max.single forging in 5T

|

1

|

|

3T electrical hydraulic hammer

|

Max.single forging in3T

|

1

|

|

Air hammer

|

Max.single forging from250kg to 1000kg

|

7

|

|

Forging operation machine

|

Max.singe forging from20T-5T

|

7

|

|

Heat treatment Furance

|

Max.8000*5000*1500mm

|

11

|

|

CNC driling machine

|

Max.5000mm

|

2

|

|

Vertical lathe

|

From 1600 to 5000mm

|

60

|

|

Horizontal lathe

|

Max.5000mm

|

70

|

|

Band sawing machine

|

260-1300mm

|

36

|

<6> Certfiticates List:

| Certificates list of Jiangyin Fangyuan |

| ISO9001:2008 |

ISO14001:2004 |

PED Certificate |

| ABS Certficate |

BV Certficate |

DNV Certificate |

| RINA Certficate |

GL Certficate |

LR Certficate |

| CCS Certficate |

NK Certficate |

KR Certficate |

| API-6A Certficate |

API-17D Certficate |

CNAS Certficate |

<7> Company Introduction:

|

Jiangyin Fangyuan Ringlike Forging Flange Co.Ltd was established in 1993.It’s the member of the Confederation of Chinese Metalforming Industry, Chinese wind energy association, China petroleum & Petro-chemical Equipment Industry Association.

As the leading forging manufacturer in China, our company is specialized in manufacturing forged rings, forged discs, forged shaft ,flanges,valve forging and pressure vessel forgings. We could provide you good quality forgings with competitive pirces.

The company covers a total area of 100,000 m2 (square meters), building area of 70,000 m2(square meters). There are 600 staffes in the company. Among them, there are 138 senior engineers and technicians. We also have our own testing center lab. which is able to do chemical analysis, metalloscope test, spectrometer test, mechanical property test and Ut test.

T

he company has been proved by ISO9001,ISO14001, TUV, API,LRS, GL,BV, ABS,DNV, CCS ,RINA,KR and NK. For more information ,you can contact me freely.

The GE,SKF ,ABB and Siemens are our main forgein customers now.I hope that my company could have the opportunity to established a long-term cooperative relationship with you.I hope to receive your inqury soon.

|

<8> Products process:

The forgings manufacturing and inspecting process are showed in the following picture :

<9>. Service & Inquiry Note:

1.Sourcing matching products Which are related to forged rings,flanges,shafts ,blocks and valves etc.

2.Tracing all products after sales by our professional team

3.Offering professional suggestions to achieve your cost effective aim when you choose the material of the products.

we are pleased to provide customers with best services in consulting,purchasing,transportation, installation, and after-sales services.

For your convenience and saving your time, to quote you with bests price,please read the details as bellow:

(1) Stteel grade

(2) Dimensions and drawings

(3) Techniacall specification

(4) Inspection requirements

1.Antirust treatment will be retreated before packing (except stainless steel).

2.After antirust treatment or no need rust carry out sponges and winding membranes package.

3.All the products are packed in fully enclosed wooden cases. Wooden case is free fumigation and suitable for shipping, wooden inwall has anti bump and moistureproof film.

4.At the wooden case bottom have 180mm supporting leg, convenient forklift and crane lifting rope handling.

5.After packing finished use steel seal to sealing and fixing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!