Product Description:

Steel Metal Forging is a highly specialized manufacturing process that plays a crucial role in producing components with superior strength, durability, and precision. Utilizing the forging process, raw steel materials are shaped under intense pressure to create metal parts that meet rigorous industrial standards. This technique ensures enhanced mechanical properties, making Steel Metal Forging an ideal choice for various demanding applications, especially in the automotive sector. Automotive Metal Forgings produced through this method exhibit exceptional toughness and resistance to wear and fatigue, which are essential qualities for vehicle safety and performance.

The manufacturing process of Steel Metal Forging involves two primary types of runners: cold and hot. Cold forging is performed at or near room temperature, which results in a finished product with excellent surface finish and high dimensional accuracy. This method is advantageous for producing intricate components that require precise tolerances. On the other hand, hot forging involves heating the steel metal above its recrystallization temperature before shaping. Hot forging allows for easier deformation of the material, enabling the creation of larger and more complex parts without compromising the steel’s structural integrity. Both cold and hot forging techniques are extensively used to manufacture Automotive Metal Forgings, ensuring that the final products meet the strict quality standards demanded by the automotive industry.

Thread types are another critical aspect of Steel Metal Forging, as they determine how components will be assembled and function in various mechanical systems. Our product range includes Thread Type AB, Type D, Type F, and Type T, each designed to meet specific engineering requirements. Type AB threads are commonly used for their strong holding power and resistance to loosening under vibration, an essential feature in automotive applications. Type D threads offer enhanced durability and are typically employed in high-stress environments. Type F and Type T threads provide specialized solutions for fastening and assembly, contributing to the versatility and reliability of the forged components. The availability of these thread types ensures that our Steel Metal Forging products can be tailored to a wide array of automotive and industrial uses.

Surface treatment processes such as tempering and annealing are integral to optimizing the properties of Steel Metal Forgings. Tempering involves heating the forged steel to a specific temperature below its critical point and then cooling it, which improves toughness and reduces brittleness. This treatment enhances the fatigue resistance of Automotive Metal Forgings, making them more reliable under cyclic loads and operational stresses. Annealing, on the other hand, softens the steel by heating it and allowing it to cool slowly, which relieves internal stresses and improves machinability. Both tempering and annealing contribute to the superior performance and longevity of steel forged components, ensuring they maintain their structural integrity even in the most demanding environments.

The wheel material used in our Steel Metal Forging products is 40NCD7, a high-quality alloy steel known for its excellent strength, wear resistance, and toughness. 40NCD7 is particularly suited for automotive applications where components are subjected to significant mechanical stress and wear. The use of this alloy steel in the forging process guarantees that the final products not only meet but often exceed industry benchmarks for performance and durability. Our commitment to utilizing premium materials like 40NCD7 underscores the reliability and excellence of our Automotive Metal Forgings.

In summary, our Steel Metal Forging products are manufactured through advanced forging processes, including both cold and hot forging techniques, to deliver components that exhibit outstanding mechanical properties and precision. With a diverse range of thread types—AB, D, F, and T—and vital surface treatments such as tempering and annealing, our forged steel parts are engineered to perform exceptionally in automotive and other heavy-duty applications. The incorporation of 40NCD7 steel further enhances the strength and longevity of these components. Whether you require durable Automotive Metal Forgings or specialized steel forged parts, our products offer unmatched quality, reliability, and performance to meet your most stringent demands.

Features:

-

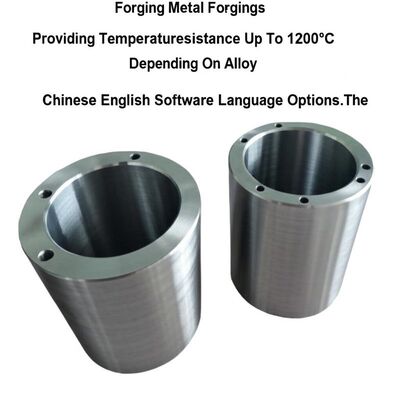

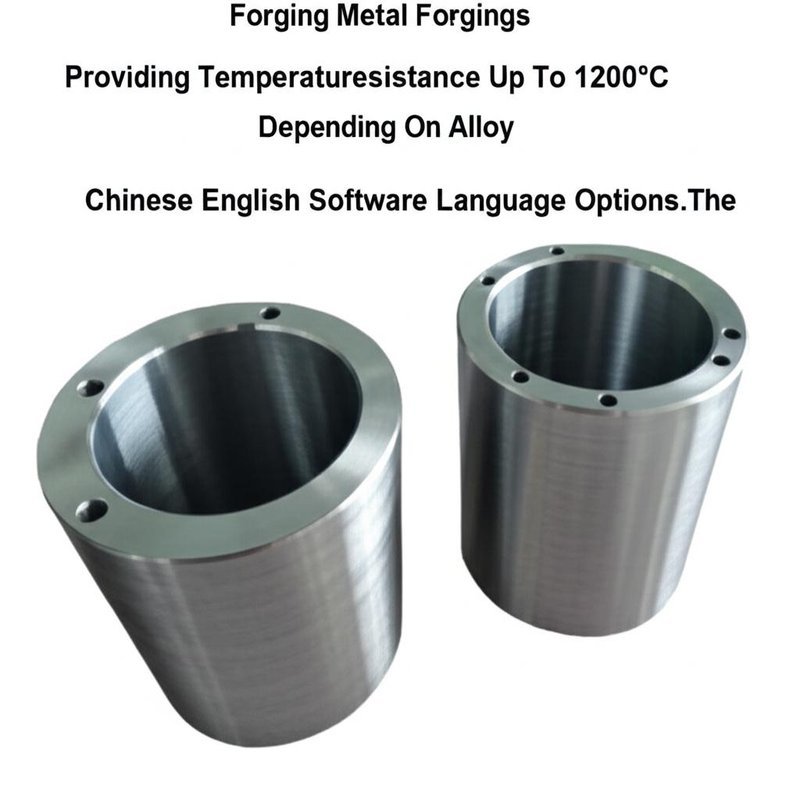

Product Name: Metal Forgings

-

Software Language: Chinese / English

-

Wheel: 40NCD7

-

Max Resolution: 1680 X 1050

-

Machine Design: As Per Customers' Special Requirements

-

Origin: China

-

Custom Metal Forging tailored to meet specific needs

-

High Strength Metal Forgings for enhanced durability

-

Precision Metal Forging ensuring accurate and consistent results

Technical Parameters:

|

Machine Design

|

As Per Customers' Special Requirements

|

|

Shaping Mode

|

Plastic Injection Mould

|

|

Surface Treatment

|

Tempering, Annealing

|

|

Manufacturing Process

|

Forging

|

|

Machine Material

|

Casting Parts Assembly

|

|

Wheel

|

40NCD7

|

|

Max Resolution

|

1680 X 1050

|

|

Unit Weight

|

Wooden Box / Plywood Box

|

|

Origin

|

China

|

|

Thread

|

Type AB, Type D, Type F, Type T

|

Applications:

Industrial Metal Forgings produced by the renowned brand fy, originating from China, are essential components in a wide range of applications and scenarios. These metal forgings are crafted using advanced casting parts assembly techniques and shaped through precise plastic injection mould processes. With sizes ranging from 15mm to 500mm and a unit packaging weight managed carefully in wooden or plywood boxes, these forgings ensure durability and reliability for various industrial needs.

One of the primary application occasions for fy’s Industrial Metal Forgings is in heavy machinery and equipment manufacturing. The robust and high-quality steel metal forging parts are designed to withstand extreme stress and pressure, making them ideal for use in construction machinery, agricultural equipment, and mining tools. Their high resolution of up to 1680 X 1050 in design precision allows for intricate and accurate components essential for heavy-duty applications.

Automotive Metal Forgings are another critical application area for fy’s products. The automotive industry demands components that offer superior strength, precision, and performance. fy’s steel metal forgings meet these requirements by providing strong, reliable parts for engines, transmissions, suspension systems, and other critical automotive assemblies. Their manufacturing process ensures that each forging maintains excellent mechanical properties and dimensional accuracy, contributing to vehicle safety and efficiency.

In addition to industrial machinery and automotive sectors, fy’s metal forgings are widely used in aerospace, marine, and energy industries. These sectors require components that can endure harsh environments and dynamic loads. The combination of casting parts assembly and plastic injection mould shaping mode allows fy to produce metal forgings with complex geometries and consistent quality, suitable for turbines, shipbuilding, and power generation equipment.

Moreover, the packaging of these metal forgings in sturdy wooden or plywood boxes guarantees secure transportation and storage, preserving the integrity of the components until they reach their final destination. This attention to detail in packaging reflects fy's commitment to quality and customer satisfaction.

In summary, fy’s Industrial Metal Forgings, including steel metal forgings and automotive metal forgings, are indispensable in numerous industrial applications. Their origin in China, combined with advanced manufacturing techniques and precise shaping methods, makes them a trusted choice for industries requiring high-performance metal components. Whether it is for heavy machinery, automotive parts, or specialized equipment, fy’s metal forgings offer unmatched reliability and precision.

Customization:

fy brand Steel Metal Forging products are expertly crafted in China using advanced forging manufacturing processes. Our Automotive Metal Forgings are produced through precise plastic injection mould shaping modes, ensuring high quality and durability. We offer Custom Metal Forging services tailored to meet your specific requirements, including various thread types such as Type AB, Type D, Type F, and Type T. Our metal forgings undergo surface treatments like tempering and annealing to enhance strength and performance. Additionally, these products exhibit excellent temperature resistance, capable of withstanding up to 1200°C depending on the alloy used.

Support and Services:

Our Metal Forgings product line is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance on material selection, forging processes, and product applications to meet your specific needs.

Our team of skilled engineers and technicians is available to assist with troubleshooting, quality control, and process optimization. We offer detailed product documentation, including specifications, handling instructions, and maintenance guidelines to help you maximize the lifespan and efficiency of your metal forgings.

In addition, we provide custom forging solutions tailored to your unique requirements, supported by advanced manufacturing capabilities and rigorous testing procedures. Whether you need prototype development, volume production, or aftermarket support, our dedicated service team is committed to delivering timely and effective assistance.

By choosing our Metal Forgings, you benefit from not only high-quality products but also a full spectrum of technical support and services designed to enhance your operational success.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!