Product Description:

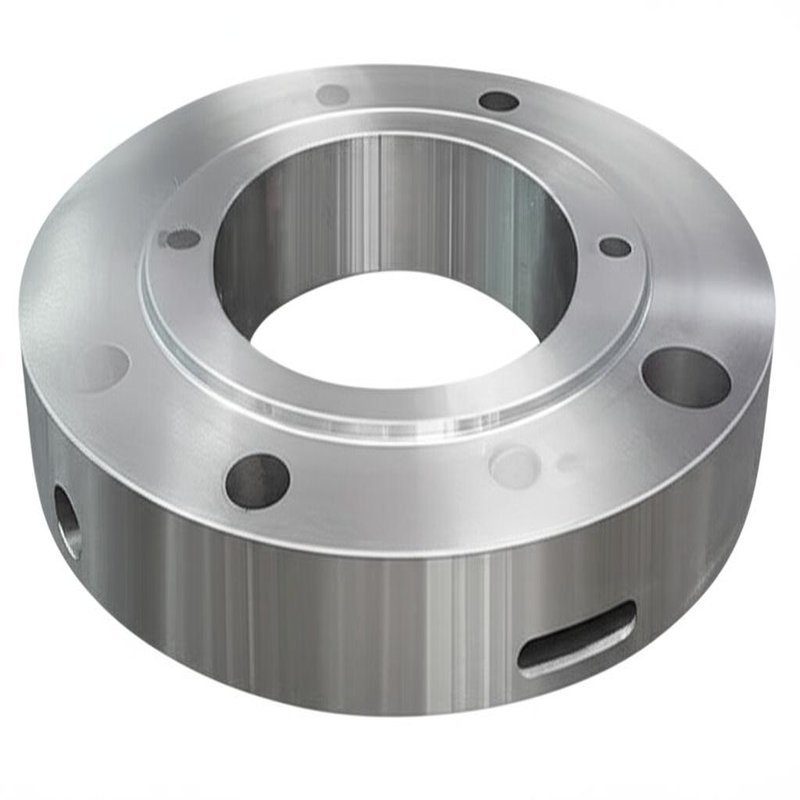

Metal forgings are a fundamental component in various industrial applications, known for their exceptional strength, durability, and reliability. Our Heavy Duty Metal Forgings are manufactured using advanced techniques that ensure superior quality and performance, making them ideal for demanding environments. These Industrial Metal Forgings are specifically designed to meet stringent specifications and are widely used across sectors such as automotive, aerospace, construction, and machinery manufacturing.

The manufacturing process of our metal forgings involves the Hot Metal Forging Process, a critical technique that imparts enhanced mechanical properties to the material. This process involves heating the metal to a high temperature, making it malleable and easier to shape without compromising its structural integrity. The hot forging method results in components with improved grain structure, increased strength, and excellent resistance to fatigue and wear, which are crucial characteristics for heavy-duty applications.

Our Metal Forgings undergo precise surface treatment processes, including Tempering and Annealing, to further enhance their performance. Tempering is applied to reduce brittleness and increase toughness, ensuring that the forged parts can withstand heavy loads and impact stresses. Annealing, on the other hand, involves heating the metal and then cooling it slowly to relieve internal stresses, improve ductility, and refine the microstructure. These treatments collectively contribute to the longevity and reliability of the metal forgings in industrial settings.

The product range features various thread types such as Type AB, Type D, Type F, and Type T, catering to diverse assembly and fastening requirements. These thread types are precision-engineered to provide secure and reliable connections, which are essential for maintaining the integrity of complex machinery and equipment. Whether it is for heavy machinery or intricate mechanical assemblies, the availability of multiple thread types ensures versatility and adaptability of our metal forgings.

Our Metal Forgings are crafted from high-quality casting parts assembly materials, combining the advantages of both casting and forging processes. This hybrid approach allows for intricate shapes and detailed features while maintaining the strength and toughness inherent in forged components. The use of casting parts assembly materials also facilitates efficient manufacturing and cost-effectiveness, providing our customers with superior products at competitive prices.

The shaping mode employed in the production of these metal forgings is Plastic Injection Mould, a technique that allows for high precision and consistency in forming complex geometries. This method is particularly beneficial for producing intricate components that require tight tolerances and excellent surface finishes. By integrating plastic injection mould shaping with forging processes, we achieve optimal control over the final product’s dimensions and mechanical properties.

In summary, our Heavy Duty Metal Forgings stand out due to their robust construction, advanced manufacturing processes, and comprehensive surface treatments. The combination of the Hot Metal Forging Process with tempering and annealing treatments ensures that these Industrial Metal Forgings deliver exceptional performance in the most challenging environments. With multiple thread types and the use of casting parts assembly materials shaped through plastic injection moulding, our product line offers unmatched versatility, strength, and reliability. These metal forgings are an excellent choice for industries seeking durable and high-performance components that can endure heavy loads, resist wear and tear, and maintain structural integrity over extended periods.

Features:

-

Product Name: Metal Forgings

-

Runner Type: Cold / Hot

-

Temperature Resistance: Up To 1200°C Depending On Alloy

-

Surface Treatment: Tempering, Annealing

-

Machine Material: Casting Parts Assembly

-

Unit Weight Packaging: Wooden Box / Plywood Box

-

Features Custom Metal Forging capabilities

-

Includes Steel Metal Forging options

-

Utilizes Hot Metal Forging Process for enhanced quality

Technical Parameters:

|

Software Language

|

Chinese / English

|

|

Origin

|

China

|

|

Shaping Mode

|

Plastic Injection Mould

|

|

Unit Weight

|

Wooden Box / Plywood Box

|

|

Temperature Resistance

|

Up To 1200°C Depending On Alloy

|

|

Size

|

15mm-500mm

|

|

Max Resolution

|

1680 X 1050

|

|

Machine Design

|

As Per Customers' Special Requirements

|

|

Payment Term

|

T/T, Western Union

|

|

Manufacturing Process

|

Forging

|

Applications:

The Metal Forgings produced by the brand fy, originating from China, are designed to meet a wide range of industrial and commercial application occasions and scenarios. These forgings are renowned for their exceptional quality and precision, making them ideal for Custom Metal Forging projects that demand high performance and durability.

One of the primary application occasions for fy Metal Forgings is in high-temperature environments, as these products can withstand temperatureresistance up to 1200°C depending on the alloy used. This remarkable heat resistance makes them suitable for industries such as aerospace, automotive, power generation, and heavy machinery, where components are often exposed to extreme heat and stress.

Due to the use of premium materials like 40NCD7 steel wheel, fy Metal Forgings offer excellent strength and toughness. This allows them to be utilized in situations requiring robust and reliable components, including gears, shafts, and structural parts in construction and manufacturing equipment. The forging manufacturingprocess ensures the metal's grain structure is refined, enhancing the mechanical properties and overall performance of the components.

Custom Metal Forging services by fy provide flexibility in terms of size, ranging from 15mm to 500mm, catering to diverse client needs. Whether producing small precision parts or large structural components, the brand’s capabilities cover a broad spectrum of requirements. Precision Metal Forging is a key attribute of fy products, achieved through advanced forging techniques and quality control, ensuring tight tolerances and superior finish in every piece.

The software language support in both Chinese and English facilitates seamless communication and coordination between fy and its global customers, enhancing the customization process and ensuring exact specifications are met. This bilingual approach is particularly beneficial for multinational projects and international collaborations.

In summary, fy Metal Forgings are perfectly suited for various application scenarios including high-temperature industrial use, heavy-duty mechanical components, and precision engineering parts. Their Custom Metal Forging and Precision Metal Forging capabilities, combined with a robust manufacturingprocess and extensive size range, make them a trusted choice for businesses seeking reliable and high-quality forged metal solutions.

Customization:

At fy, a leading brand originating from China, we specialize in Custom Metal Forging services tailored to meet your specific requirements. Utilizing the Hot Metal Forging Process, our expert team ensures superior quality and precision in every product.

Our Metal Forgings are crafted using advanced Casting Parts Assembly machines, guaranteeing durability and performance. We offer a variety of thread types including Type AB, Type D, Type F, and Type T to suit diverse applications.

Each forging undergoes a Hot Metal Forging Process that allows it to withstand temperatures up to 1200°C, depending on the alloy used, ensuring excellent temperatureresistance for demanding environments.

The shaping mode employed is Plastic Injection Mould, which provides intricate and accurate designs customized to your specifications. Additionally, we package our units securely in Wooden Box or Plywood Box for safe delivery.

Choose fy for reliable and high-quality Metal Forgings with customizable options, combining advanced Hot Metal Forging Process techniques with versatile materials and designs to fulfill your industrial needs.

Support and Services:

Our Metal Forgings product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We offer expert consultation to assist you in selecting the right forging solutions tailored to your specific application requirements. Our experienced engineers provide guidance on material selection, design considerations, and manufacturing processes.

In addition, we provide detailed product documentation, including specifications, machining guidelines, and quality assurance protocols. Our quality control team rigorously inspects each forging to meet industry standards and customer expectations.

For any technical inquiries or assistance, our support team is available to address your concerns promptly. We also offer after-sales services such as maintenance recommendations and troubleshooting support to help you maintain the longevity and reliability of your metal forging components.

Partner with us for durable, high-quality metal forgings supported by dedicated technical expertise and customer service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!