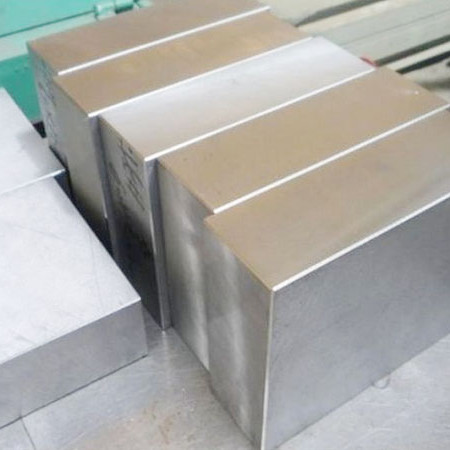

60WCrV7 Cold Tool Steel DIN 1.2550 Forged Steel 60WCrV2//6CrW2Si Steel Bar

DIN 1.2550 is a vacuum melting chrome-nickel-molybdenum alloy steel, quenched and tempered before delivery, has the following advantages: no quenching and heat treatment deformation risk; no heat treatment costs; shorten the mold production cycle; reduce the mold required Cost (for example, no need for out-of-plane deformation); molds are easy to modify; nitriding and surface hardening treatments can be applied to enhance the surface hardness and wear resistance of the mold.

| Si |

C |

W |

P |

Cr |

Mo |

| ≤0.40 |

2.00-2.30 |

0.6~0.9 |

≤0.03 |

11.00-12.50 |

≤0.35 |

Application:

Large-scale long-life plastic injection molds, such as home appliances, computer shells, and other molds; high surface finish plastic molds; blow mold; due to high hardness, can be used in the plastic mold slider; forming tools, compression

n - brake mold ( Bay plate machine model) (can apply flame hardening or nitriding treatment depending on the production needs); construct parts and shafts.

Heat Treatment:

Quenching and tempering

Mechanical Properties:

| Tensile Strength Rm Mpa:≥985 |

| Yield Strength Reh Mpa:≥835 |

| Elongation after fracture A%:≥12 |

| Reduction of area:≥45 |

| Hardness:≥229HB |

Certfiticates List:

| Certificates list of Jiangyin Fangyuan |

| ISO9001:2008 |

ISO14001:2004 |

PED Certificate |

| ABS Certficate |

BV Certficate |

DNV Certificate |

| RINA Certficate |

GL Certficate |

LR Certficate |

| CCS Certficate |

NK Certficate |

KR Certficate |

| API-6A Certficate |

API-17D Certficate |

CNAS Certficate |

Company Introduction:

Jiangyin Fangyuan Ringlike Forging Flange Co.Ltd was established in 1993.It’s the member of the Confederation of Chinese Metalforming Industry, Chinese wind energy association, China petroleum & Petro-chemical Equipment Industry Association.

As the leading forging manufacturer in China, our company is specialized in manufacturing forged rings, forged discs, forged shaft ,flanges,valve forging and pressure vessel forgings.

The company covers a total area of 100,000 m2 (square meters), building area of 70,000 m2(square meters). There are 600 staffes in the company. Among them, there are 138 senior engineers and technicians. We also have our own testing center lab. which is able to do chemical analysis, metalloscope test, spectrometer test, mechanical property test and Ut test.

The company has been proved by ISO9001,ISO14001, TUV, API,LRS, GL,BV, ABS,DNV, CCS ,RINA,KR and NK.

The GE,SKF ,ABB and Siemens are our main forgein customers now.I hope that my company could have the opportunity to established a long-term cooperative relationship with you.I hope to receive your inqury soon.

Products process:

The forgings manufacturing and inspecting process are showed in the following picture :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!